Fire Safety

Consider Masonry when building

Fire Safety

CMU's stand tall in the worst of situations

Solutions News | A Publication of SRM Concrete, producers of Decrastone | Fall 2020 Edition

Fire Awareness

Why risk it with wood frame when concrete and masonry can save an investment.

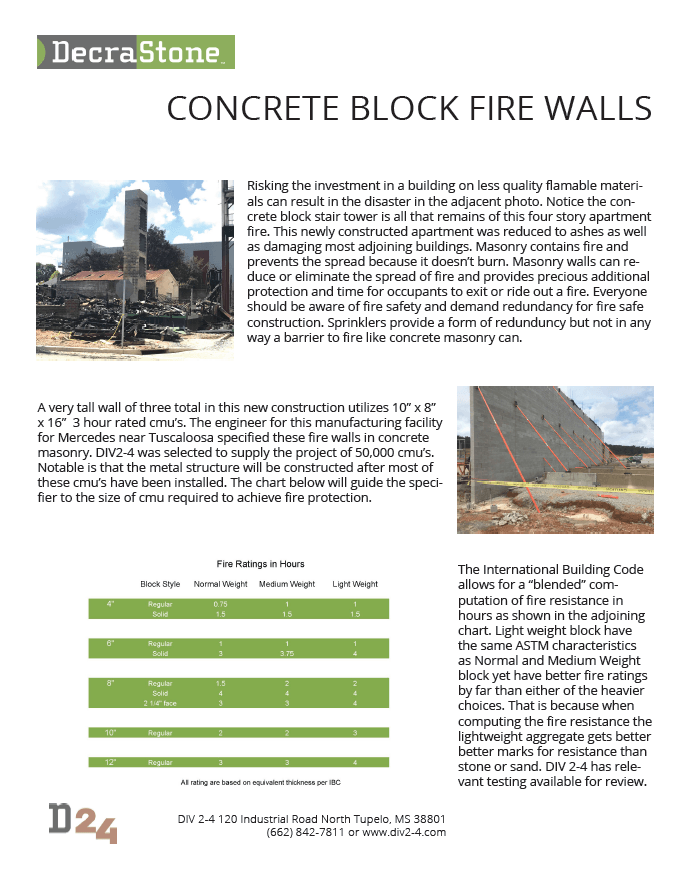

Risking the investment in a building on less quality flammable materials can result in the disaster in the adjacent photos. Notice the concrete block stair tower is all that remains of this four-story apartment fire. This newly constructed apartment was reduced to ashes as well as damaging most adjacent buildings. Masonry will contain a fire and prevent it's spread because it doesn't burn.

Masonry walls can reduce or eliminate the spread of fire and provides precious additional protection and time for occupants to exit or ride out a fire. Everyone should be aware of fire safety and demand redundancy for fire safe construction.

Sprinklers provide a form of excess fire suppression but not in any way a barrier to fire like concrete masonry can. These fires occur nationwide and are predominate on these wood frame mid-rise constructions.

Why Masonry Fire Walls?

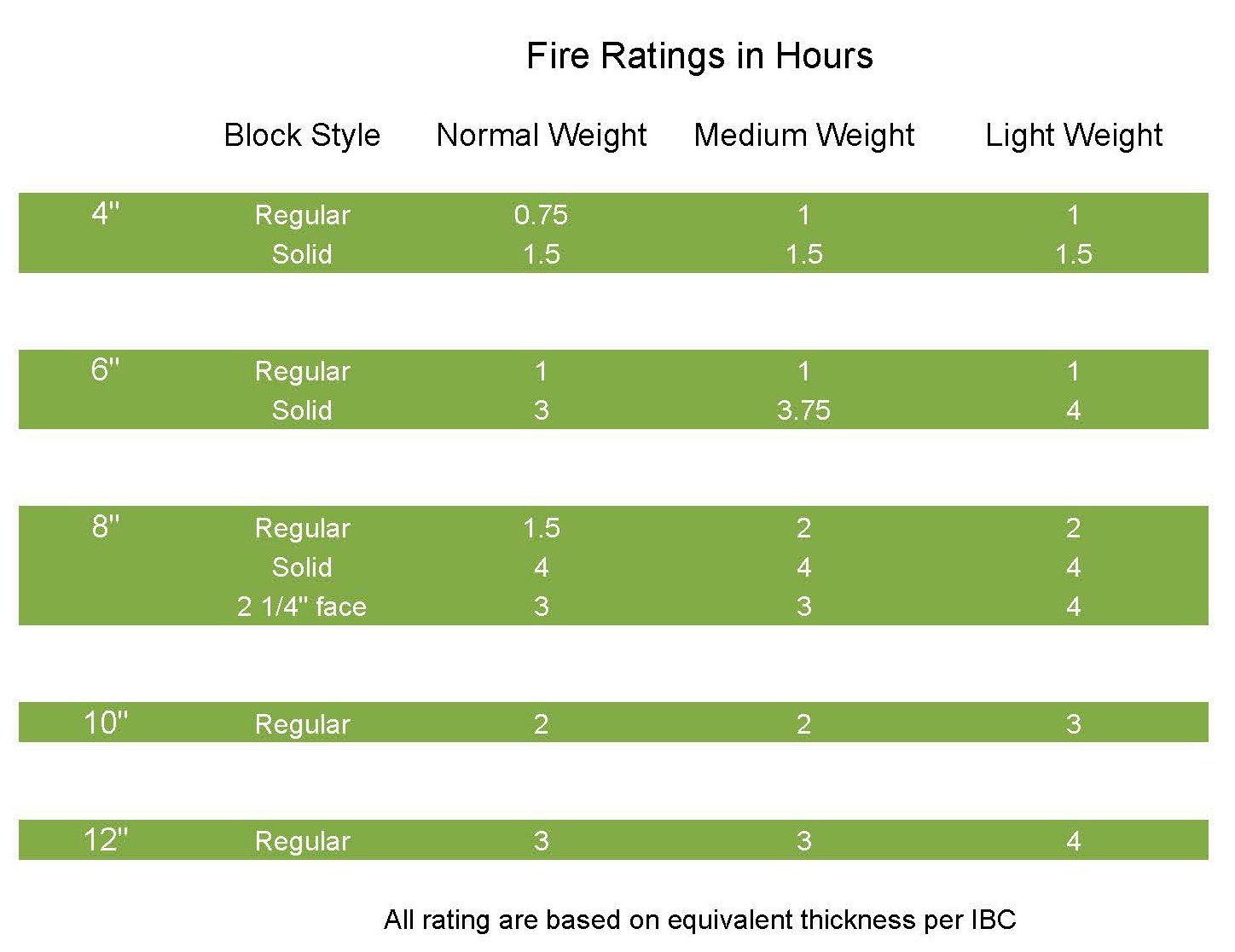

A very long and tall wall (this is one of three total) in this new construction utilizes 10” x 8” x 16” 3 hour rated CMU’s. The engineer for this manufacturing facility for Mercedes near Tuscaloosa specified these firewalls in concrete masonry. DIV2-4 was selected to supply the project of 50,000 CMU’s. Notable is that the metal structure will be constructed after most of these CMU’s have been installed. The chart below will guide the specifier to the size of CMU required to achieve fire protection.

Testing Requirements for Approval

The International Building Code allows for a “blended” computation of fire resistance in hours as shown in the adjoining chart. Lightweight block have the same ASTM characteristics as Normal and Medium Weight block yet have better fire ratings by far than either of the more massive choices. That is because when computing the fire resistance the lightweight aggregate gets better marks for resistance than the stone or sand aggregates that are primarily used in Normal and Medium Weight versions. DIV 2-4 has testing available for review.

The result is a building that its inhabitants can trust.

How do the International Building Codes and the Insurance Industry consider rating construction for fire? Both will impact the initial price and the eventual cost of any building not to mention the Return on Investment on any building.

Insurance Ratings for Fire Resistance

There are 6 different classes of construction that underwriters use.

Frame

Joisted Masonry

Non-Cumbustible

Masonry Non-Combustible

Modified Fire Resistive

Fire Resistive

Insurance Services Office Inc. (ISO) grades buildings based on what would happen with your properties in the event of a loss. For example, if you have a building that’s “frame” construction you’ll typically see a higher rate than “masonry” or a “fire resistive” building. The chances of the structure remaining intact after a fire are much less than a fire resistive building. Here are the 6 classes of construction summarized.

ISO Class 1- Frame

Buildings with exterior walls, floors and roofs of combustible material – typically wood. Masonry veneer (brick-face) or metal clad don’t change the construction class.

Frame is easy to build and economical, but burns quickly and easily. It has concealed spaces where fire can continue.

Least desirable class for underwriters.

Examples: Habitational 3-4 stories max.

ISO Class 2- Joisted Masonry

Buildings with exterior walls of masonry or fire-resistive construction rated for not less than one hour and with combustible floors and roofs. This typically includes block constructed buildings and can include heavy timber buildings.

Harder to ignite, and burns at a slower rate. There are fewer concealed spaces than frame construction and a higher rebuild rate based on less damage.

Examples: Habitational, small office or retail. 3-4 stories max.

ISO Class 3- Non-Combustible

Buildings with exterior walls, floors and roofs of noncombustible or slow-burning materials.

Easy to erect, economical to build and uses materials that don’t easily burn.

Typically steel construction. Can easily lose strength under high temperatures, typically seen in fires.

Examples: Warehouses and manufacturing facilities.

ISO Class 4- Masonry Non-Combustible

Buildings with walls made of masonry, consisting of concrete block, reinforced masonry and can be combined with steel framing.

Roof construction is typically made of heavy steel.

No wood framing in the roof which helps keep the structure standing in a large loss. Walls are a minimum of 1 hour fire resistive.

Examples: Shopping centers, office buildings, warehouses and schools.

ISO Class 5- Modified Fire Resistive

Building construction consists of fire resistive materials such as masonry and protected steel materials not less than 4” thick.

Fire resistive less than 2 hours, but greater than 1 hour.

Roofing deck is heavy steel frame with concrete poured on steel deck or pre-poured concrete.

Examples: High and mid-rise office buildings, apartments and condo buildings.

ISO Class 6- Fire Resistive

Fire resistive for not less than 2 hours for walls, floors and roofs.

Typical wall construction is masonry at a minimum of 4 inches thick, hollow masonry is a minimum of 8 inches thick.

Floors and roofs are a minimum of 4 inches thick and fire resistant a minimum of 2 hours.

Reinforced concrete of frame or steel are well protected and are also a minimum of 4 inches thick for walls, roof and floors.

Examples: High-rise office buildings, condos and parking garages.

International Building Code

TYPES OF CONSTRUCTION

TYPE I

– This concrete and steel structure, called fire resistive when first built at the turn of the century, is supposed to confine a fire by its construction. This type of construction in which the building elements listed in IBC Table 601 are of non-combustible materials, such as concrete and steel. The roof is also of non-combustible material, such as concrete or steel.

TYPE II

– This type of building has steel or concrete walls, floors, and structural framework similar to type I construction; however, the roof covering material is combustible. The roof covering of a type II building can be a layer of asphalt waterproofing, with a combustible felt paper covering. Another layer of asphalt may be mopped over the felt paper.

TYPE III

– This type of constructed building is also called a brick-and-joist structure by some. It has masonry-bearing walls but the floors, structural framework, and roof are made of wood or other combustible material; for example, a concrete-block building with wood roof and floor trusses. Fire-retardant-treated wood framing complying with IBC Sec. 2303.2 shall be permitted within exterior wall assemblies of a two-hour rating or less.

TYPE IV

– These buildings have masonry walls like type III buildings but the interior wood consists of heavy timber. In a heavy-timber building, a wood column cannot be less than 8′′ thick in any dimension and a wood girder cannot be less than 6′′ thick. The floor and roof are plank board. One difference between a heavy timber type IV building and type III construction is that a heavy-timber type IV building does not have plaster walls and ceilings covering the interior wood framework. The details of type IV construction shall comply with the provisions of 602.4.1 through 602.4.7. Fire-retardant-treated wood framing complying with IBC Section 2303.2 shall be permitted within exterior wall assemblies with a two-hour rating or less.

TYPE V

– Wood-frame construction is the most combustible of the five building types. The interior framing and exterior walls may be wood. A wood-frame building is the only one of the five types of construction that has combustible exterior walls. This is the typical single-family home construction method. These buildings are built with 2 x 4 or 2 x 6 studs and load-bearing walls, wood floor trusses, or wood floor joist and wood roof framing.