RainBloc

RainBloc

Solutions News | A Publication of SRM Concrete, producers of Decrastone | Fall 2021 Edition

RainBloc®

Water Repellent

Incorporated in each DecraStone concrete block and a must for mortar joints

Stopping water infiltration into a building is probably one of the most important aspects of any specification requirements. The reason we use RainBloc is explained here by our production team.

A Premium Water Repellent

Why RainBloc?

Every successful product is the fruit of hard work, and this applies to every DecraStone product. Intuition alone is not enough to create a product that people will love and use. We use the industry's most forward-thinking admix suppliers for the best CMU that we can possibly produce. Some of the benefits of RainBloc include the following: Resists rainwater penetration, fights against mold and mildew, maintains masonry colors, resists efflorescence.

RainBloc is a polymeric-based admix that is permanent and durable and provides protection for the full-wall thickness of the masonry wall that has incorporated the RainBloc in both block and mortar.

-

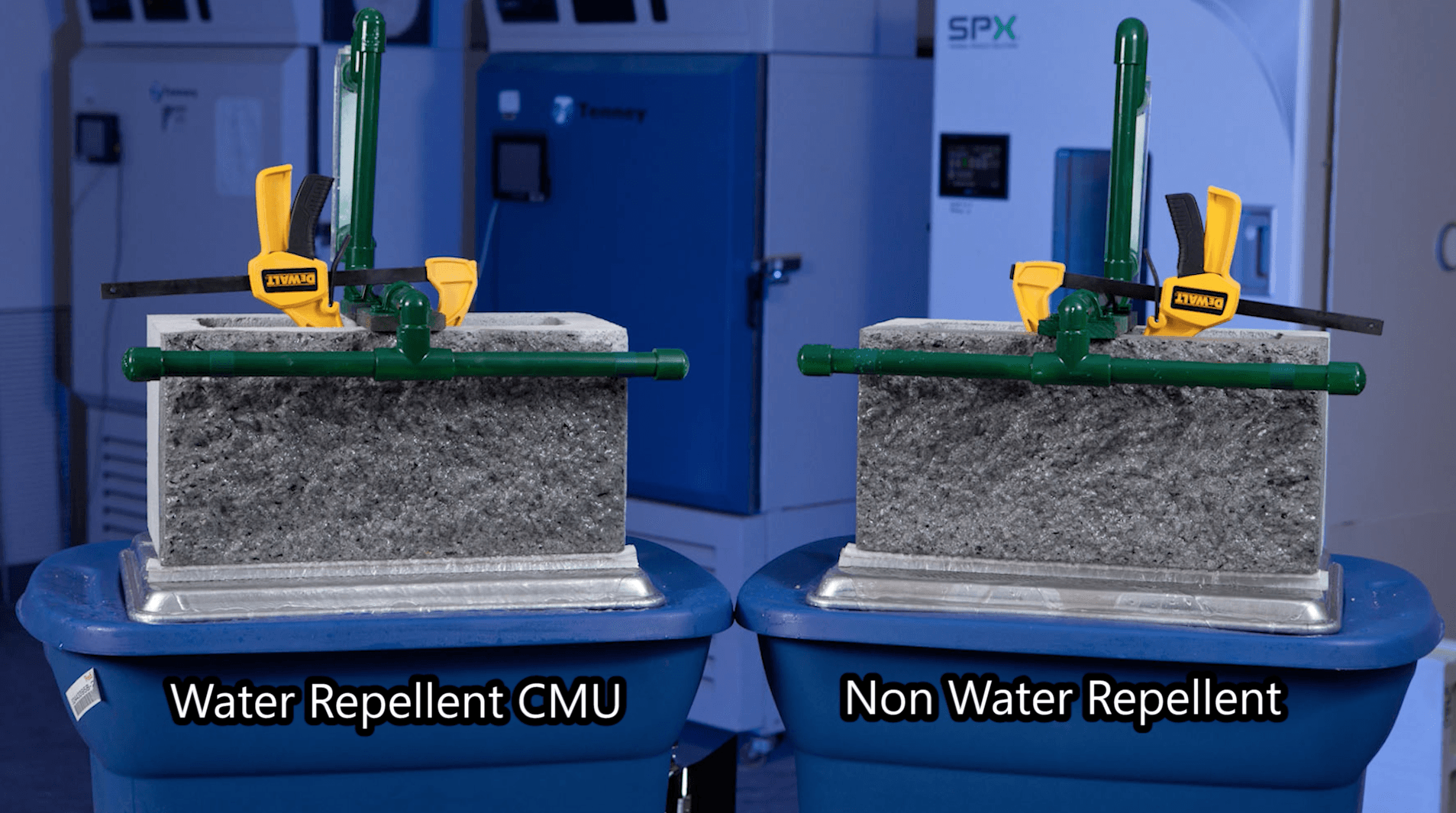

Block at the start of testing

ButtonThese block are both dry. The one on the left has RainBloc and the right one has no water repellency.

-

The water spray bar

ButtonA continuous water spray, regulated for pressure, applies water across the face of the block only to test for leaks.

-

After 4 hours of spray bar testing

ButtonNote the block on the right is soaked thru the face and around the corner

-

Interior after 4 hours

ButtonThe right block is wet on the interior of the cell.

This test method correlates well with ASTM E514 "Standard Test Method for Water Permeance of Masonry" and NCMA CMU WR2-09 "Standard Test Method for Spray Bar Test of Concrete Masonry".

Testing Requirements for Approval

The following is taken from the ACM RainBloc Rain Water Penetration Resistance for Masonry Construction.

"Spray Bar Test Method

The RainBloc Spray Bar Test Method subject individual concrete masonry units to continuous water pressure from a standardized spray bar at a rate of 120 gallons of water per hour.

After four hours of continuous exposure, each unit is evaluated using standardized pass/fail criteria. This test method correlates well with ASTM E 514.

A producer's concrete masonry units must pass this rigorous test to be a certified RainBloc producer.

Testing Procedure

- Masonry units are manufactured with RainBloc admixture with assistance from an ACM Chemistries technical service representative.

- Masonry units are shipped to ACM Chemistries for evaluation using the RainBloc Spray Bar Test Method.

- Units are tested for compliance with the ASTM Unit Specification designated for the type of unit manufactured (ASTM C55, C90, C129, C744).

The CMU producer receives a RainBloc Certification Report upon successful compliance with the water repellency performance criteria established by ACM Chemistries, Inc. This report provides evidence to specifiers about the performance and certification of compliance for the water repellent units made by the manufacturer.

Each certified RainBloc producer receives a performance report that includes

- RainBloc Spray Bar Test Method results

- masonry unit physical properties

- certificate of performance

[Note to Specifier: It is strongly recommended by ACM Chemistries, Inc. that the following section be included in your project specification, especially for larger scale projects. The pre-installation conference can establish your strong desire to enforce the requirements for water-repellency, proper flashing techniques, and the use of weeps. Coordinate with Division 01 Section "Project Management and Coordination."]"

The Result is a Dry Wall

Related Topics

-

Continuing Education

PDF of the 1 hr courseA Rainbloc certified program is available for 2019. Call or email for an appointment.

-

RainBloc Brochure

PDF of brochure -

Stopping Wind Driven Rain

Pdf of BrochureRainBloc for concrete block and for mortar is imperative for a solid wall.

-

Most often questions

PDF of literatureUnderstand why RainBloc works and why it is part of all DecraStone products.

-

Cleaning Masonry w/ RainBloc

PDF of document -

Rainbloc Mortar Spec

PDF of Document -

RainBloc Block Spec

PDF of document -

RainBloc - Mortar

PDF of brochure